Tube Welding Line

RT50 Tube mill machine

This RT50 tube mill machine is the most popular tube mills in 2018 especially for producing the pipes for EMT, IMC, RCS .

This RT50 tube mill machine is the most popular tube mills in 2018 especially for producing the pipes for EMT, IMC, RCS .

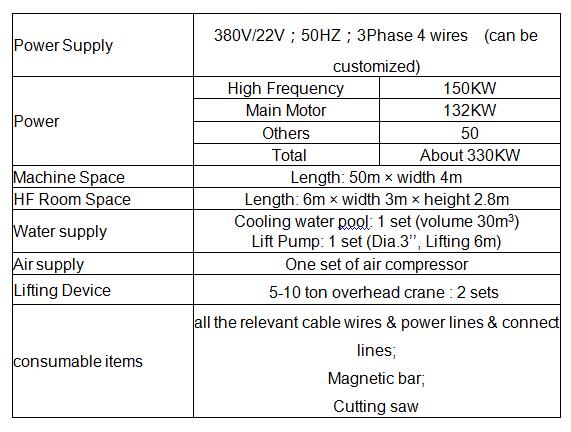

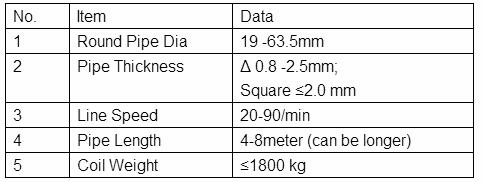

Main Parameter:

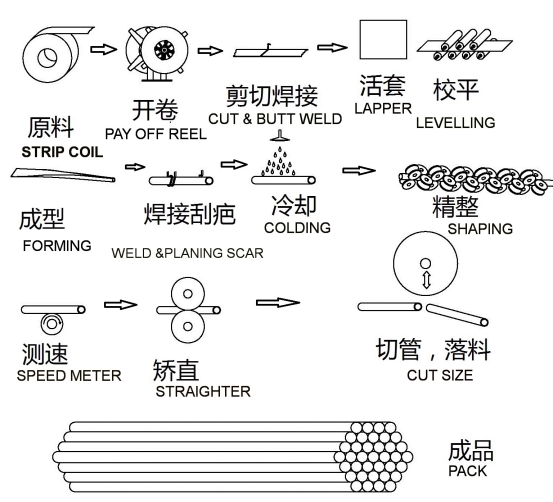

Working Process

Machine Configuration:

1. Uncoiler

The equipment is located in the forefront of the whole tube making line. When in need to use this , take the coil into the head of the uncoiler and then expand it, the coil will be driven to the following units. The picture show s the manual expansion type, and the hydraulic and pneumatic types can be adopted also.

2.Vertical Accumulator

The steel strips stored in it shall be enough to ensure main machine to run continuously while welding two coiled strips.

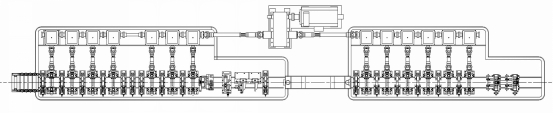

3.Main Machine : 7 stands forming + 6 stands sizing

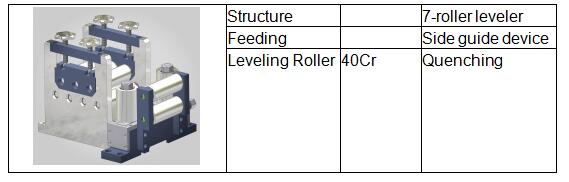

3.1 7-roller Leveler

It is located in the forefront of the forming unit.

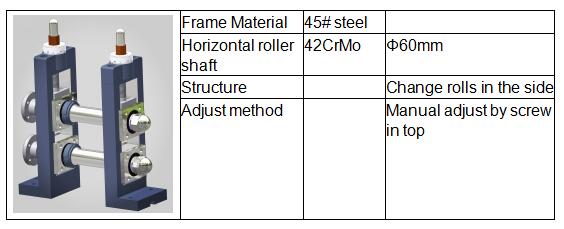

3.2 Horizontal Roller Device

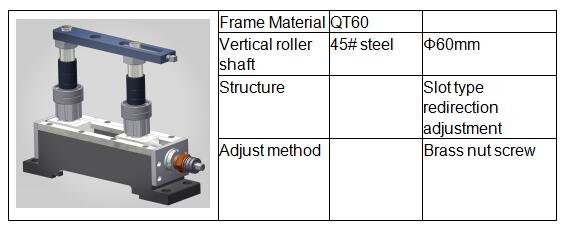

3.3 Vertical Roller Device

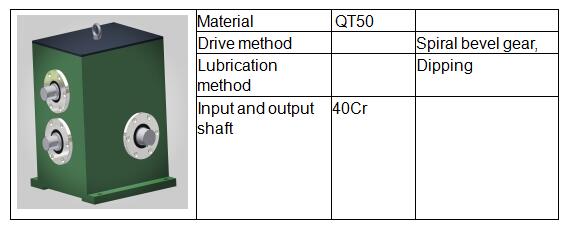

3.4Sub-drive gear box

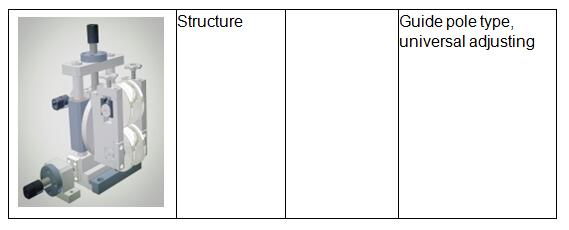

3.5 Guiding device

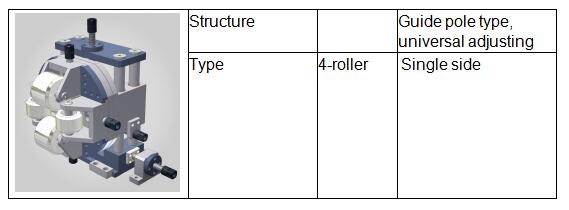

3.6 Extruding Device

3.7 Deburring Device

With two groups scraper frame, pneumatic draw back

3.8 Straightening (Turk’s head)

3.9. Main Drive Unit

3.10 Main machine Arrangement Form

4.Computer Tracking Saw

It is used to cut the finished pipes into desired length as set in the touch screen.

(1) Cutting thickness : 0.8-2.5mm

(2) Cutting O.D. : 19-63.5mm

(3) Cutting Length : 4-8m

(4) Cutting tolerance : ≤±3 mm

(5) Cutting motor : AC motor 18.5KW

(6) Driving motor : AC motor 15KW

5.Supply by User