Tube Welding Line

RT76 Steel Pipe Making Machine

The RT76 tube mill is intended for manufacturing of round/square pipe of Φ25mm-Φ90mm with Thickness of 1.5mm–4.0mm from cold-rolled, hot-rolled and galvanized coil strip.

The RT76 tube mill is intended for manufacturing of round/square pipe of Φ25mm-Φ90mm with

Thickness of 1.5mm–4.0mm from cold-rolled, hot-rolled and galvanized coil strip.

Features of RT76 Pipe Making Machine

This RT76 Steel pipe making machine is used to produce industrial steel pipes by means of unclosed tubular blank with its subsequent welding into tube, edge heating by means of solid state high-frequency welder, longitudinal seam welding in rolls of tube welding machine, cooling, further sizing or shaping and on-stream cutting of endless tube in measured lengths.

Finished product will be of round, square, rectangular pipe or special pipe LTZ and D shape.

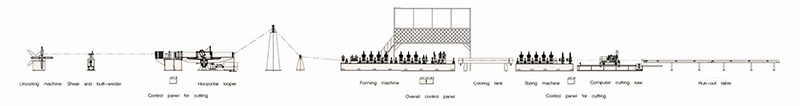

Process Flow of Steel Pipe Mills

{Steel Tape}→→ Double-head un-coiler →→Strip-head Cutter and welder→→Spiral Accumulator→→Forming section Flattening unit + Main driving unit+Forming unit +Guide unit +High frequency induction welding unit +squeeze Roller)+ De-burr frame →→Cooling unit →→Sizing unit and straightened →→Cutting saw→→ Run-out table

Technical Parameter for RT76 HF Tube Mills

1.1. INPUT

(1). Material : Hot & Cold Rolled Steel Strips (Q195.Q235)

(2). Thickness: 1.5-4.0mm (SQ, REC Pipe: ≤3.0mm)

(3). Slit width : 78-280mm

(4). Coil Weight (Slit Coil) : Max.3.0 tons

(5). Coil ID: 450-550mm

(6). Coil OD : Max.1200mm

1.2. OUTPUT

(1). Round pipe dia.: 25 – 90mm

Wall thickness: 1.5-4.0mm

(2). Square rectangular pipe : 20x20 - 70x70mm

Wall thickness : 1.5-3.0mm

(3) Length : 4-8meter

(4). To-length accuracy : ≤±3mm

1.3 LINE DATA

(1). Line Direction (optional) : From Right to Left or from Left to Right

(Viewed from operator side; will be double confirmed)

(2). Line Speed: 20-70/min

(3). Power for equipment motor: 312KW

(4). Power for HF electric : 300KW (Solid State)

Machine Configuration

(1) Double-side Un-coiler (Hydraulic expansion)

(2) Shear and butt welder

(2) Horizontal accumulator

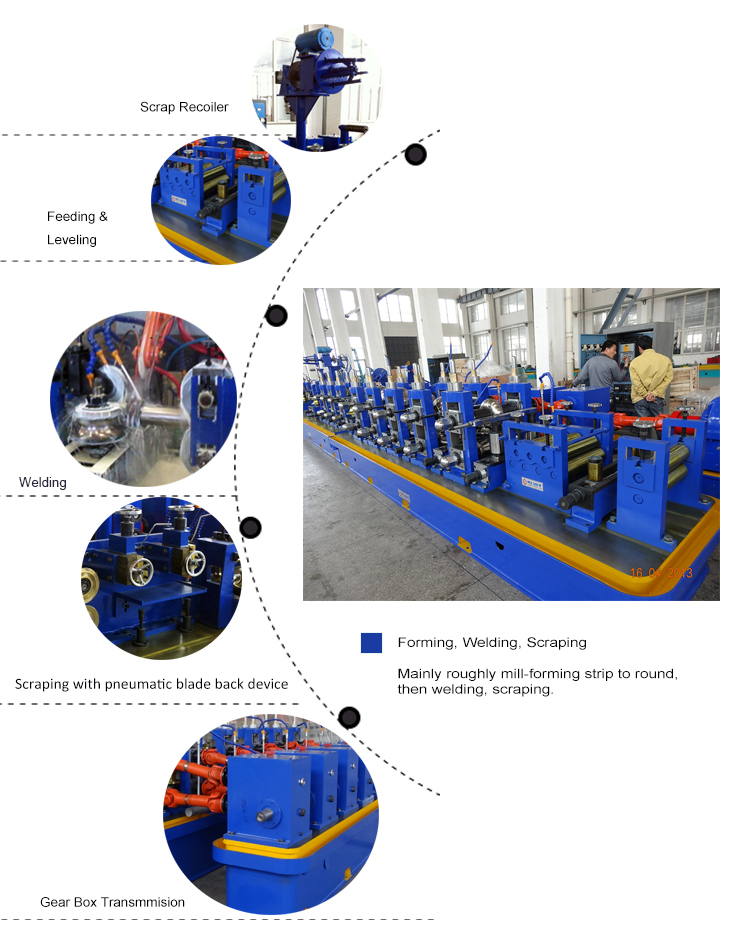

(3) Forming, Welding and Sizing mill

A) Feeding & Leveling device

B) Forming machine

C) Guiding, extruding, Welding & scraping device

D) One set of cooling water tank

E) Sizing mill

F) Main Driving System

(4) Computer-controlled flying Cutting Saw (Circular Saw Cutting)

(5) Finished Pipe Passing Conveyor (Run out table)

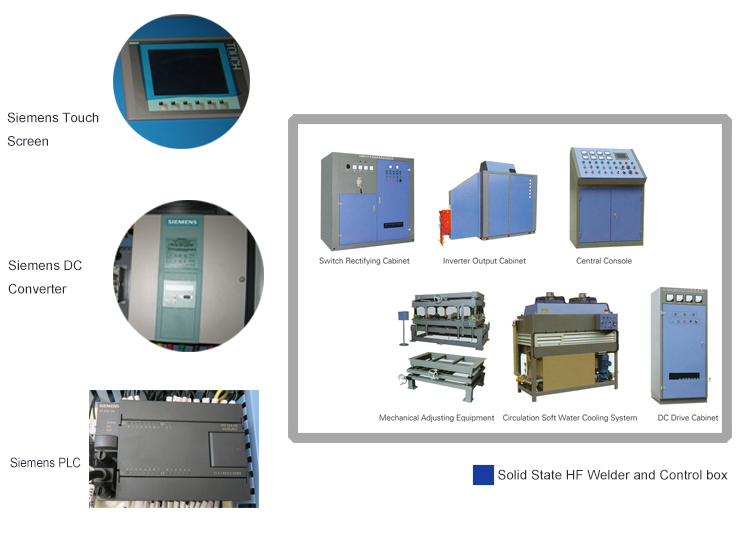

(6) HF Electric

(7) Pneumatic System

(8) Electrical System with PLC Control and DC Drive Control System