The RT60 tube mill is intended for manufacturing of round/square pipe of Φ19mm-Φ63.5mm with Thickness of 1.0mm–3.0mm from cold-rolled, hot-rolled and galvanized coil strip.

Features of R60 Pipe Making Machine

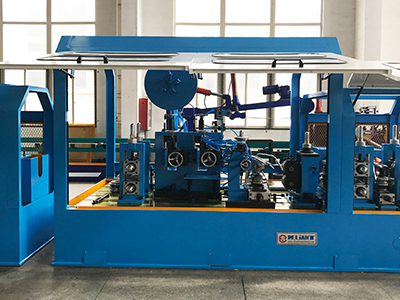

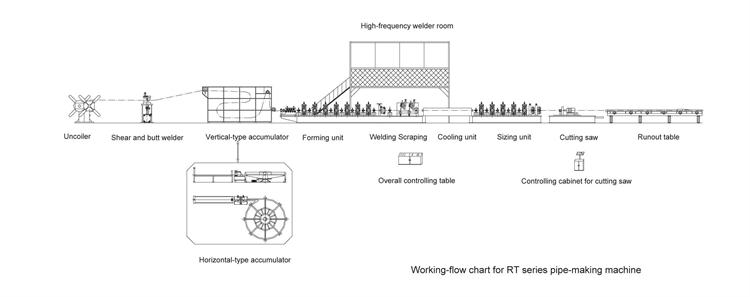

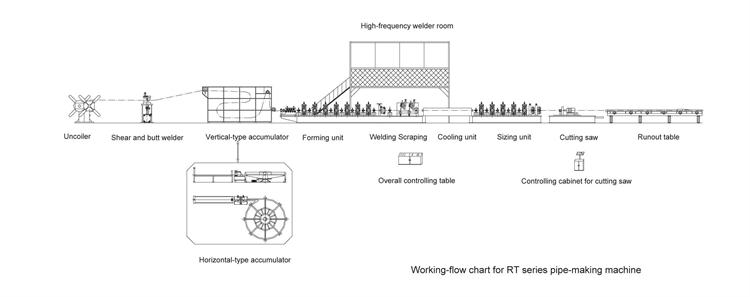

This RT60 tube mills is used to produce straight seam automatic oil pipes and tubes by means of steel slit strips with its subsequent welding into tube, edge heating by means of solid state high-frequency welder, longitudinal straight seam welding in rolls of tube welding machine, cooling, further sizing or shaping and on-stream cutting of endless tube in measured lengths.

Finished product will be of round, square, rectangular pipe.

Process Flow of Steel Pipe Mills

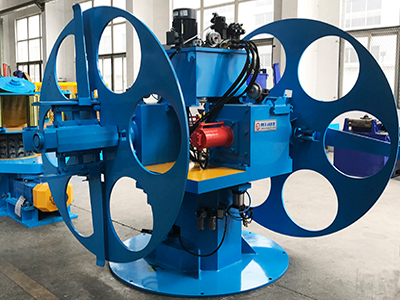

Steel strips ---- double side decoiler ---- shear and butt welder ---- vertical accumulator ---- pinch roll + leveler, forming device, welding device ---- cooling unit ---- sizing and turk’s head ---- computer saw --- run out rack

Steel Pipe Specification

1. Pipe diameter: ¢19–¢63.5mm

Pipe Thickness: 1.0– 3.0mm

2. Square Pipe: 15×15-50×50mm

Rectangle Pipe: 20X10mm –40X60mm

Pipe Thickness: 1.0– 2.5mm

3. Pipe Length: 4.0m – 8.0m

4. Length Tolerance: ≤±3mm

Steel Tape Specification

1. Material: Low Carbon steel (δb≤500Mpa, δs≤235Mpa)

2. Steel Tape: Inner diameter: Φ450-520mm

Outer diameter: Φmax=1300mm

Strip steel width: 60mm-200mm

Strip steel thickness: 1.0–3.0mm

The maximum weight: 2 tons

Line Specification

1. Line Direction (optional) : From Right to Left or from Left to Right

2. Line Speed : 20-80/min

3. Power for equipment motor : about 230KW

4. Power for HF electric: 200KW (Solid State)

Product Applications