CNC Turret Punching

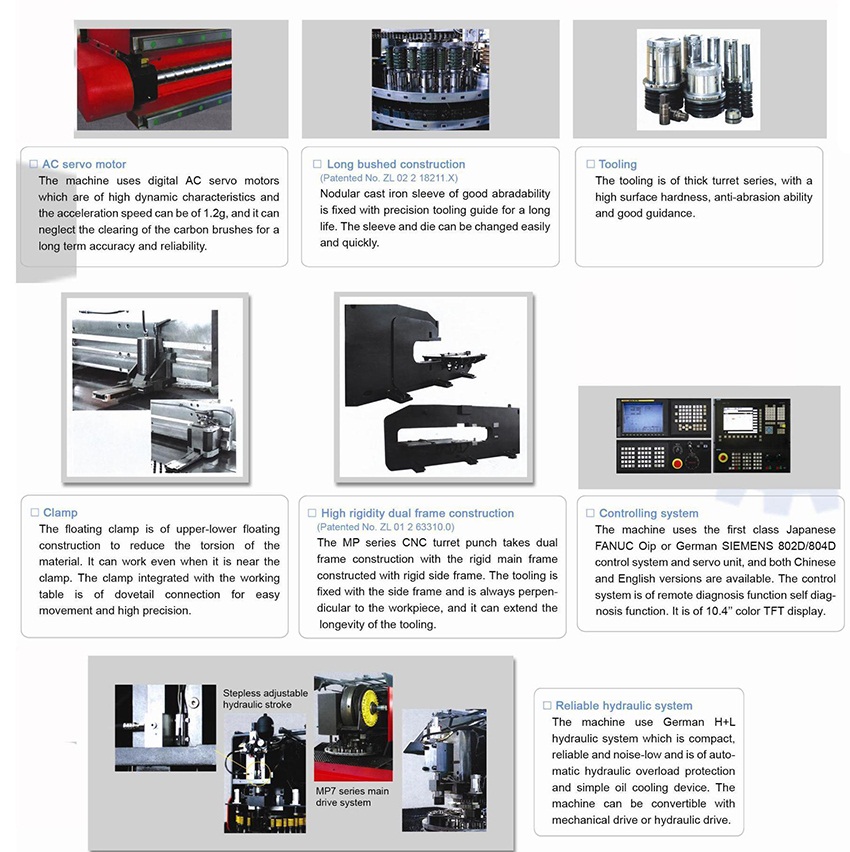

1. MP10 series CNC turret Punch is of enclosure structure (ZL2004 2 0108852.4), which receives tempering treatment. 2. German H+L hydraulic system enjoys reliable performance and low power consumption (11KW) CNC system FANUC Oip or SIEMENS 840D is used on this series punch. 3. The turret (ZL 02 2 18211.X)

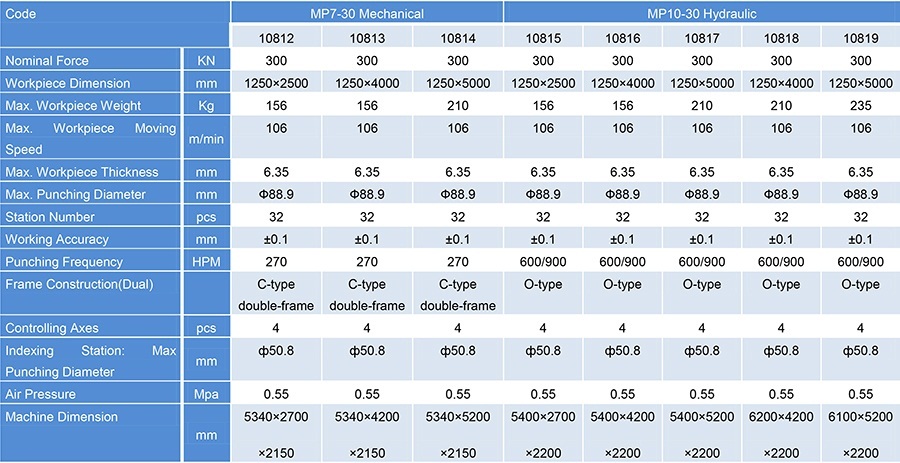

MP series

1. MP10 series CNC turret Punch is of enclosure structure (ZL2004 2 0108852.4), which receives tempering treatment.

2. German H+L hydraulic system enjoys reliable performance and low power consumption (11KW)

CNC system FANUC Oip or SIEMENS 840D is used on this series punch.

3. The turret (ZL 02 2 18211.X) features long sleeve structure and the index station had sectional wheel and worm mechanism.

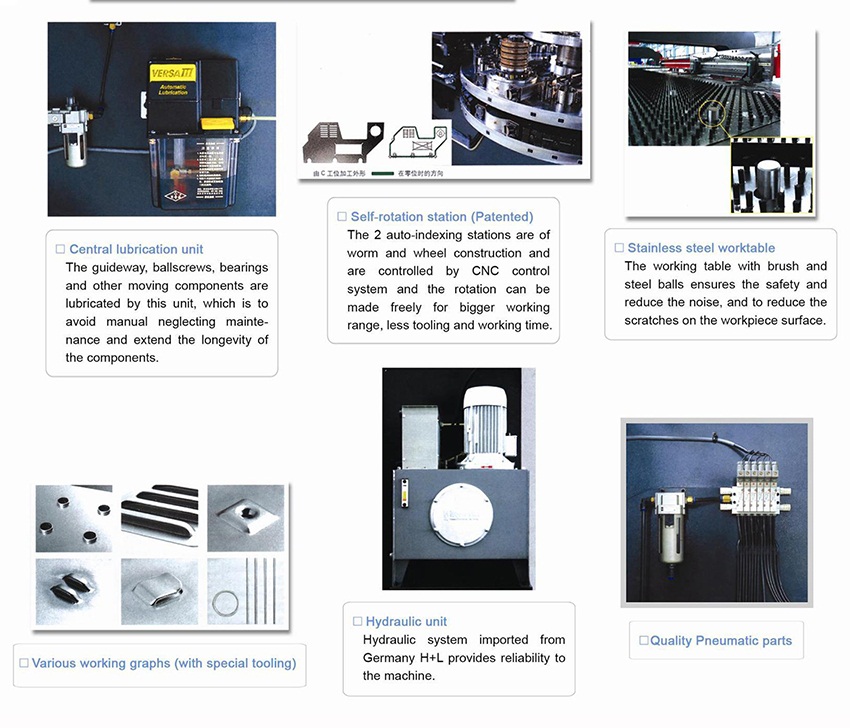

4. This series punch consists of international pneumatic and electrical components, imported long travel ballscrews, the liner guideway, worktable with brush, and steel balls auto central lubrication device and auto floating clamps.

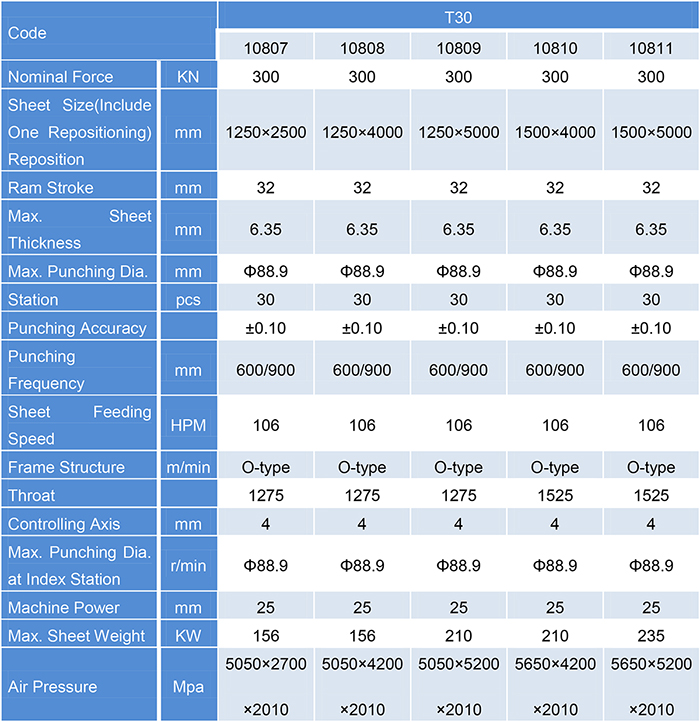

T30

1. Wide closure-type frame

2. Streamline body with side pin-positioning

3. Sleeve structure and thick turret

4. Accurate positioning, good guiding, high accuracy adjustable worm and gear mechanism

5. German H+L hydraulic station with high performance and low energy-consumption

6. Special Japanese FANUC Oip CNC control

7. Long ball screw and guide way with high speed and auto-lubrication

8. Auto floating clamp

9. Stainless worktable with steel ball and brush