Elbow Forming Machine

Since 1980, when the first Gorelocker came onto the marker, many improvements like speed increase, closing system etc. have been integrated, but a real step ahead was only recently. This method and machine produce a now type of double seam (patent in most countries), what renders any gaskets or sealant unnece…

Since 1980, when the first Gorelocker came onto the marker, many improvements like speed increase, closing system etc. have been integrated, but a real step ahead was only recently.

This method and machine produce a now type of double seam (patent in most countries), what renders any gaskets or sealant unnecessary. The bends are not only tight, our gain but also on rigidity and reliability.

Advantages:

1. No sealant or gasket needed

2. Constant & accurate in seam quality

3. Air tightness class C

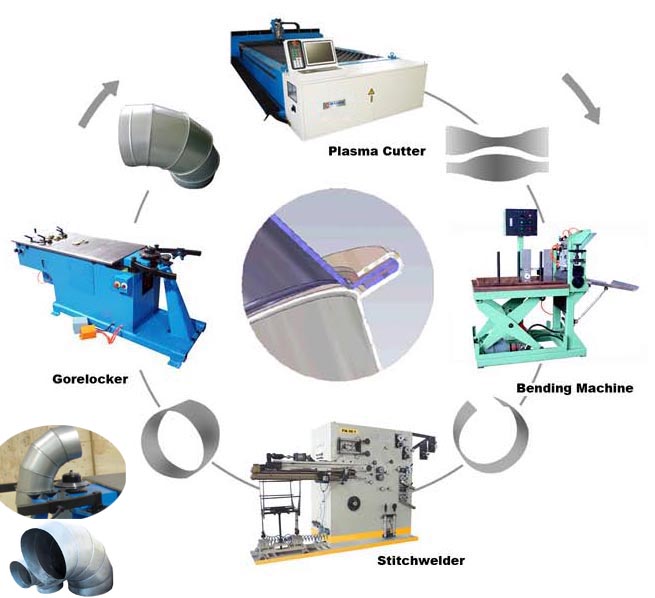

The above picture shows the full low cost process for high quality segment bend; Including the Stitch welder for longitudinal and airtight seam.

Tight seam: Air tightness Class C

Diameter range: 160-1250mm

Material thickness:

1. Galv. Steel: 0.4-0.9mm

2. Stainless Steel: 0.4-0.7mm

3. Aluminum: 0.4-0.9mm

4. Production time: 2.0min (bend dia. 200mm)

Standard seam: Air tightness Class B

Diameter range: 125-1250mm

Material thickness:

5. Galv. Steel: 0.4-1.25mm

6. Stainless Steel: 0.4-1.0mm

7. Aluminum: 0.4-1.25mm

8. Production time: 1.5min (bend dia. 200mm)