GR8 Panel RFM

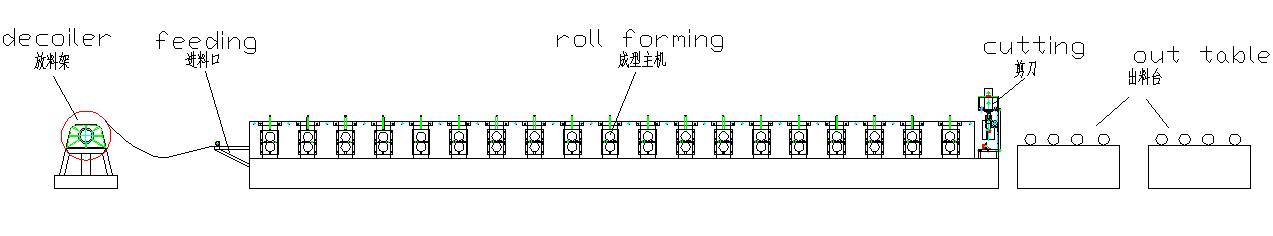

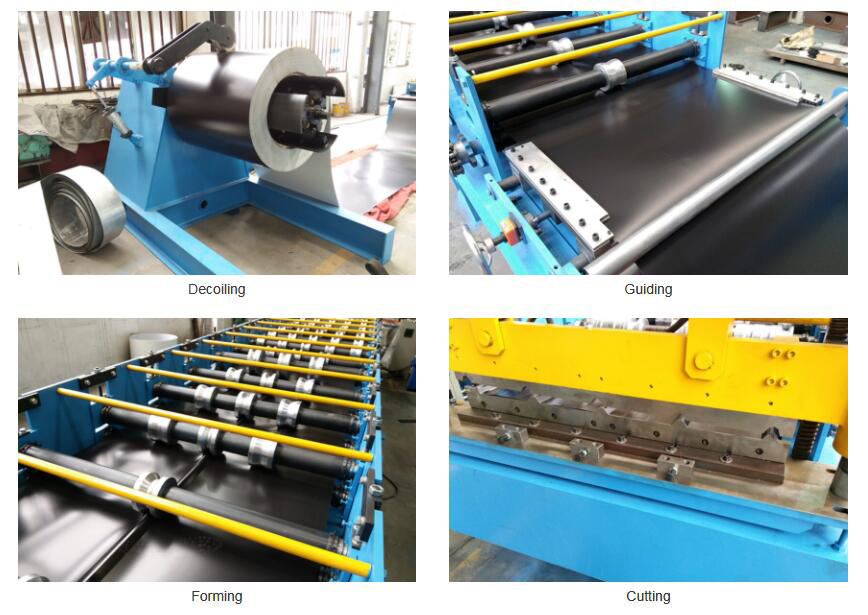

Roll forming machine includes in decoiler, sheet guiding equipment, roll forming system, post-cutting equipment, hydraulic station, electric controlling system and run out table for product.

We can also offer the FINISHED PRODUCTS for kinds of special profiles according to customers’ drawings, such as:

1. fireproof and heat insulation door and window partition

2. fireproof curtain wall according to customers’ drawings

3. Photovoltaic Solar support

Roll forming machine includes in decoiler, sheet guiding equipment, roll forming system, post-cutting equipment, hydraulic station, electric controlling system and run out table for product.

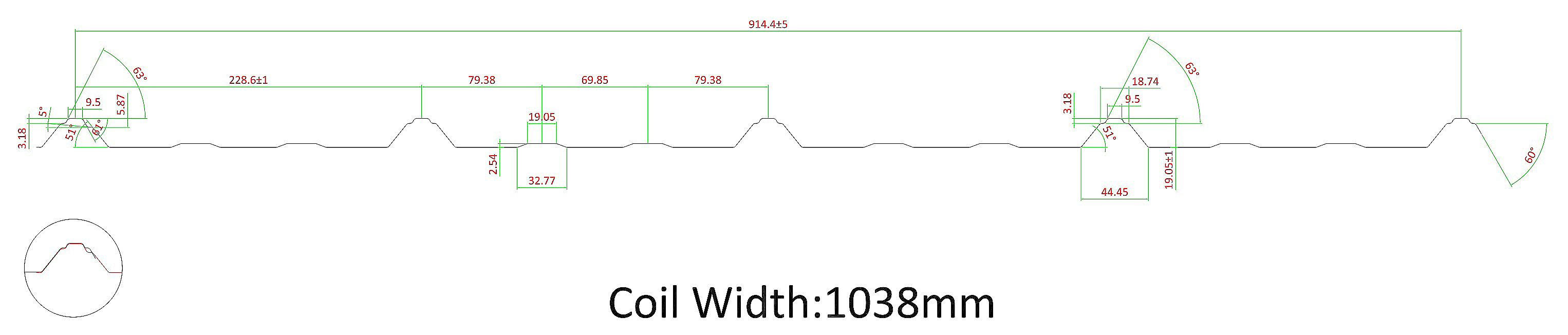

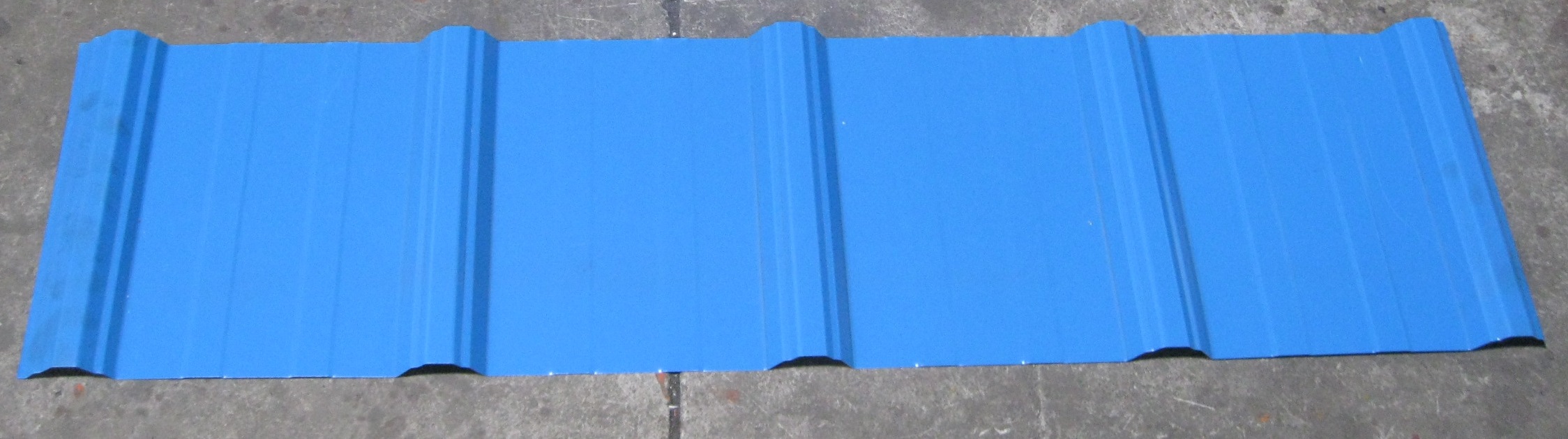

The “Ag Panel” (GR8 panel) Machine produces one of the most popular Metal Roofing / Metal Building profiles used today. A very strong panel used as a Roof Panel and or Wall Panel. The machine will accept approximately a 41" wide coil stock (26-29 ga. Steel), giving you a 38" wide panel and 36" coverage with the panel overlap.

These panels are primarily used in commercial and industrial metal roof and siding applications.

Providing high weather-resistance and extended roof life, AG panels are a great choice for both commercial and residential roofing projects in the Southeastern US. AG panels are low rib and offer a sleek look for homes and agricultural building. Chosen as an economical metal roofing solution, AG panels are very durable and are suitable for open frame projects.

Roll Forming System for GR8 panel

1. Anti-rust roller: CNC machine tooled, Plated with 0.05mm hard chrome .

2. Heat treatment: Heat treatment for cutting frame to remove the steel stress, to avoid deformation.

3. Cutter blade: Cr12 mould steel with quenched treatment, long life time.

4. High precision: shafts for rollers are tooled by grinding machine at least twice. Rollers are CNC processed to ensure precision performance.

5. People originate: introduced Mitsubishi PLC with touch screen. Friendly man-machine interaction.

6. Excellent services: Technician can be sent to your factory to install the machine and train your workers. Lifttime services for our machines.

7. All-in-house source: We are "All-in-house source" factory to ensure quality and delivery of your machines.

8. Long life: Ensure you our produce machine’s lifetime more than 15 years.

9. Certificate: ISO 9001, CE,

1. Anti-rust roller: CNC machine tooled, Plated with 0.05mm hard chrome .

2. Heat treatment: Heat treatment for cutting frame to remove the steel stress, to avoid deformation.

3. Cutter blade: Cr12 mould steel with quenched treatment, long life time.

4. High precision: shafts for rollers are tooled by grinding machine at least twice. Rollers are CNC processed to ensure precision performance.

5. People originate: introduced Mitsubishi PLC with touch screen. Friendly man-machine interaction.

6. Excellent services: Technician can be sent to your factory to install the machine and train your workers. Lifttime services for our machines.

7. All-in-house source: We are "All-in-house source" factory to ensure quality and delivery of your machines.

8. Long life: Ensure you our produce machine’s lifetime more than 15 years.

9. Certificate: ISO 9001, CE,

Process Flow for Steel Panel Roll Forming Machine

Hydraulic Un-coiler—Roll Forming—Cutting—out table

Hydraulic Un-coiler—Roll Forming—Cutting—out table