Sandwich Panel Forming Line

The production line is semi-automatic manufacturing heat insulation sandwich panels. Machine Feature - H plate, tong & groove panel plate production available - Corrugated panel with various joints option available - EPS or rock wool & glass wool panel available

We can also offer the FINISHED PRODUCTS for kinds of special profiles according to customers’ drawings, such as:

1. fireproof and heat insulation door and window partition

2. fireproof curtain wall according to customers’ drawings

3. Photovoltaic Solar support

EPS,rock wool RFM

The production line is semi-automatic manufacturing heat insulation sandwich panels.

Machine Feature

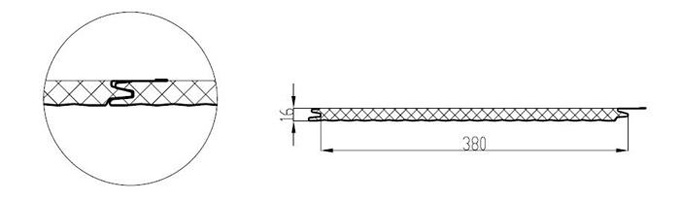

- H plate, tong & groove panel plate production available

- Corrugated panel with various joints option available

- EPS or rock wool & glass wool panel available

- Joint-hidden panel plate with various joint and plate type available

- Continuous automatic production available

- PLC (programmable logic controller) combined with touch screen apply convenient and reliable operation

- Automatic length to cut and count available

- Complete accessory equipment available

- Nonstandard panel type as customer requirement

- Flexible option for customer practical need

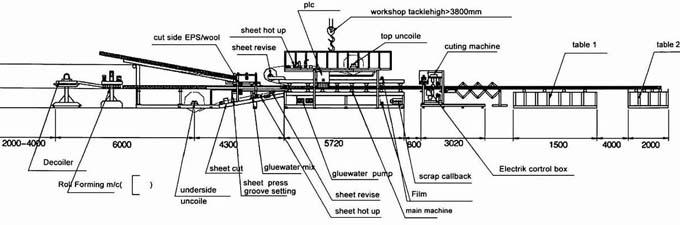

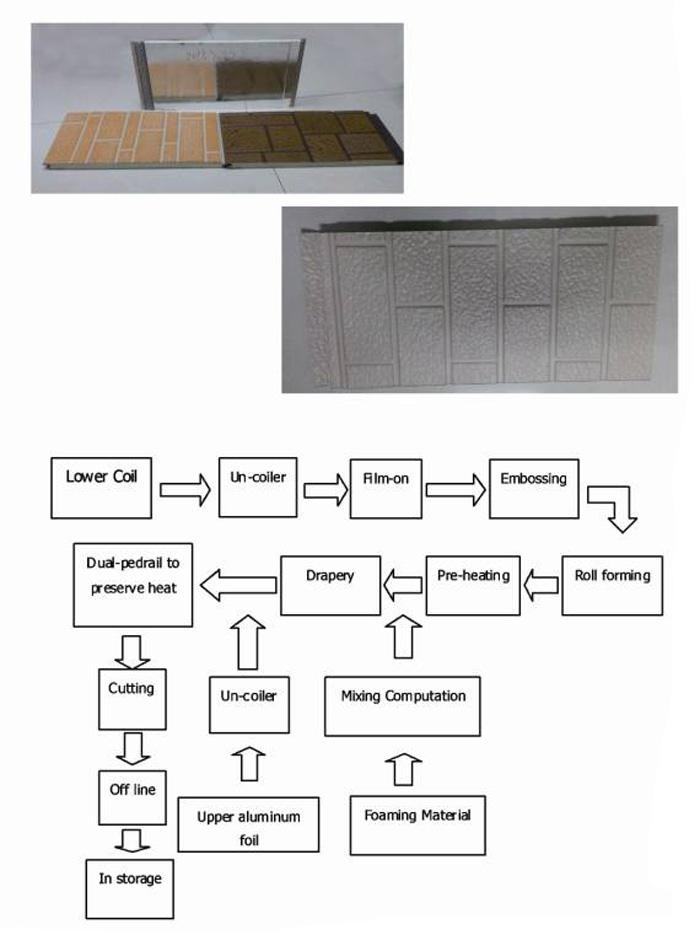

Process Flow

10T Manual de-coiler --- steel sheet feeding guider --- roll forming machine --- corrugated profile (flat steel sheet) feeding guider ---complex machine --- synchronically tracking cutter --- 6m stacking table

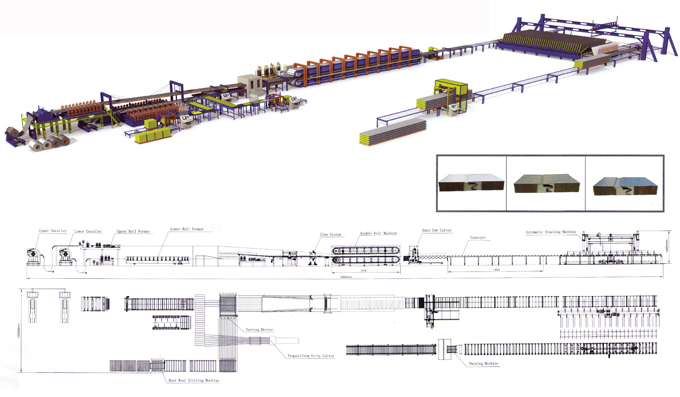

PU+Rock Wool Sandwich producion Line with Auto feeding+Auto Stacker+Auto wrapping

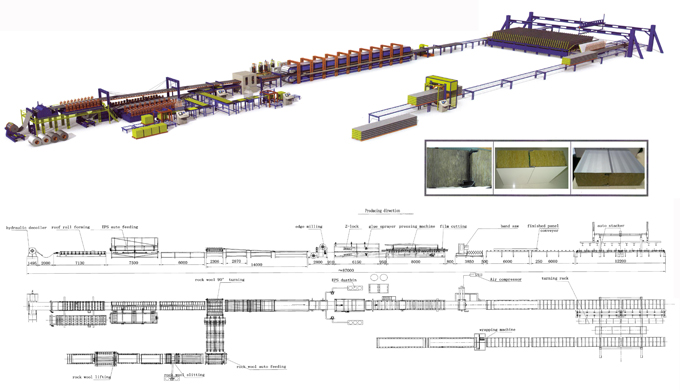

XPS/Rock Wool Sandwich Production Line with Auto feeding+Auto Stacker+Auto wrapping

PU Continuous RFM

This energy conservation PU sandwich panel is composed with machinery, chemicals, hydraulic pneumatic and temperature control technology. The automatic and multi-functional production line consists of un-coiler, film-on, pre-cut device, roll forming machines, pre-heating system, PU foaming machine, solidifying, cutting, and transportation.

PU Discontinuous RFM

Discontinuous PU sandwich panel production line is mainly used for producing PU sandwich panel. This line includes foaming machine and press machine. The major spare parts of foaming machine are imported. Generally speaking, this line has many advantages such as high precision by continuous injecting, material mixing uniform, stable performance, convenient operation, high production efficiency, etc.

Process Flow

Loading --- Decoiling --- Forming --- Filming --- Cutting --- Loading in worktable --- Sending to Press Molding --- Closing --- Pouring + Foaming + Curing + Pressing --- Leaving Press Molding --- Demoulding --- Opening --- Demoulding