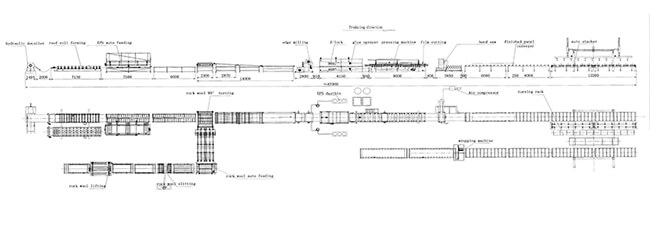

Hydraulic Decoiler

Roll Forming Machine

Rock Wool/EPS/XPS Auto Feeding

Edge Milling

Z-lock Roll Forming

Glue Sprayer

Sandwich Panel Laminator

Film Cutting

Band Saw Cutter

Conveyor

Auto Stacker

Wrapping Machine

Sandwich Panel RFM

Rock Wool/EPS/XPS Sandwich Panel Line is to produce a sandwich panel by the insertion of rock wool or EPS/XPS into a space between color coils.

We can also supply the customized machines.

We can also offer the FINISHED PRODUCTS for kinds of special profiles according to customers’ drawings, such as:

1. fireproof and heat insulation door and window partition

2. fireproof curtain wall according to customers’ drawings

3. Photovoltaic Solar support

Features of Rock Wool + PU Sandwich Panel Line (A type)

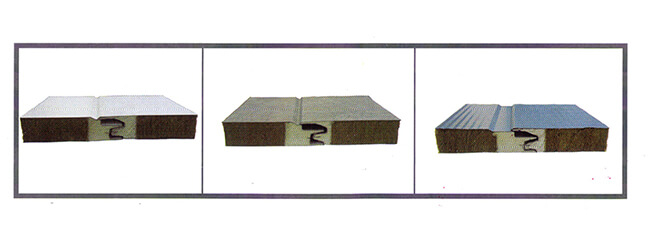

Panel from the continuous sandwich panel production line is a composite structure consisting of two external facings and an insulating core. The core can be flexible with Polyurethane, Rock Wool, Glass Wool, PIR, Phenolic or EPS. Various profiles are available according to customer’s requirement with pre-painted steel sheets, PVC sheets, Aluminum paper or other similar supports.

The continuous sandwich panel production line has a large scale production capacity. It allows a uniform distribution of the reactive mixture, a homogeneous density, suitable physical and mechanical characteristics.

Roof panels, wall panels and door panels are made mainly of metal section support and polyurethane insulating mass.

The capacity of the continuous line is 3-7m/min, length of the production line is 100m. the size of the final panel is 3-18m long, 900-1200mm wide, 20-150mm thick, the valid length of double belt conveyor is 24m, the total power is 300KW.

Applications of Rock Wool + PU Sandwich Panel Line

This product mainly provides clean rooms, operation rooms and clean workshops with complete fireproof and anti-static clean system, including walls, suspended ceilings and anti-static workbenches, etc.

In full consideration of static prevention, cleanness, fire prevention and other professional demands, take beautiful appearance, moisture resistance, acoustic performance, durability and other physical and chemical properties into account for the purpose of providing perfect safety protection system.