Auxiliary Equipment

1.Special double chain drive, oblique gear & worm speed reducer is adopted 2.Four-roller device wrapped with polyamide adhesive 3.Inverter control is adopted: fast, stable & safe 4.Separate control panel allows remote operation

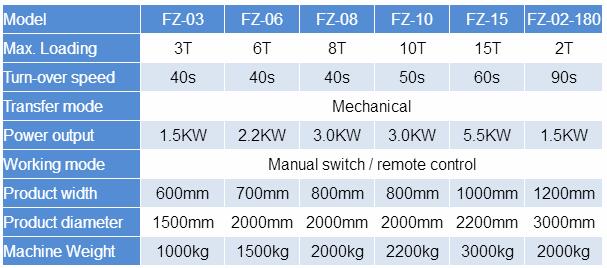

A.Coil Upender

Special double chain drive, oblique gear & worm speed reducer is adopted

Four-roller device wrapped with polyamide adhesive

Inverter control is adopted: fast, stable & safe

Separate control panel allows remote operation

Multiple position limit system ensures safe operation

The machine can be stopped at random; object will stay in current position

B.Wrap-Packing Machine (Horizontal)

Application:

This machine is suitable for bars, shapes or plates floor board, aluminum shapes, etc.

Features:

HMI&PLC are adopted.

Ring speed is controlled by converter and wrapping mode can be adjusted according to requirement.

Photocell sensor is adopted, film carriage at definite position.

Safety, satiability, efficiency and easy to operate.

Max. Packing Diameter | 350mm |

C.Wrap-Packing Machine (with Rotary Arm)

Features:

PLC & HMI are adopted.

Unmanned working mode. All steps include extending load, feeding film, wrapping, cutting, smoothing, conveying package can be finished automatically.

Indicator alarms automatically when the trouble occurs.