Combined lines are the ideal solution for average production rates as they allow to cut blanks or slit coils in one single installation, that is, they can be used as cut-to-length or slitting lines in accordance with the users needs.

It can process the material up to 2000 mm width, thicknesses of up to 3 mm. The lines can be supplied with start-stop cutting systems, high-precision levelers of four or six heights, computer controlled. Edge trimming may be incorporated. In slitting mode they have quick change slitters, moving tensioning devices with incorporated leveler, high-capacity recoiler and extraction from coil without banding.

It takes totally computer-controlled with diagnosis, automatic coil feed and quality control.

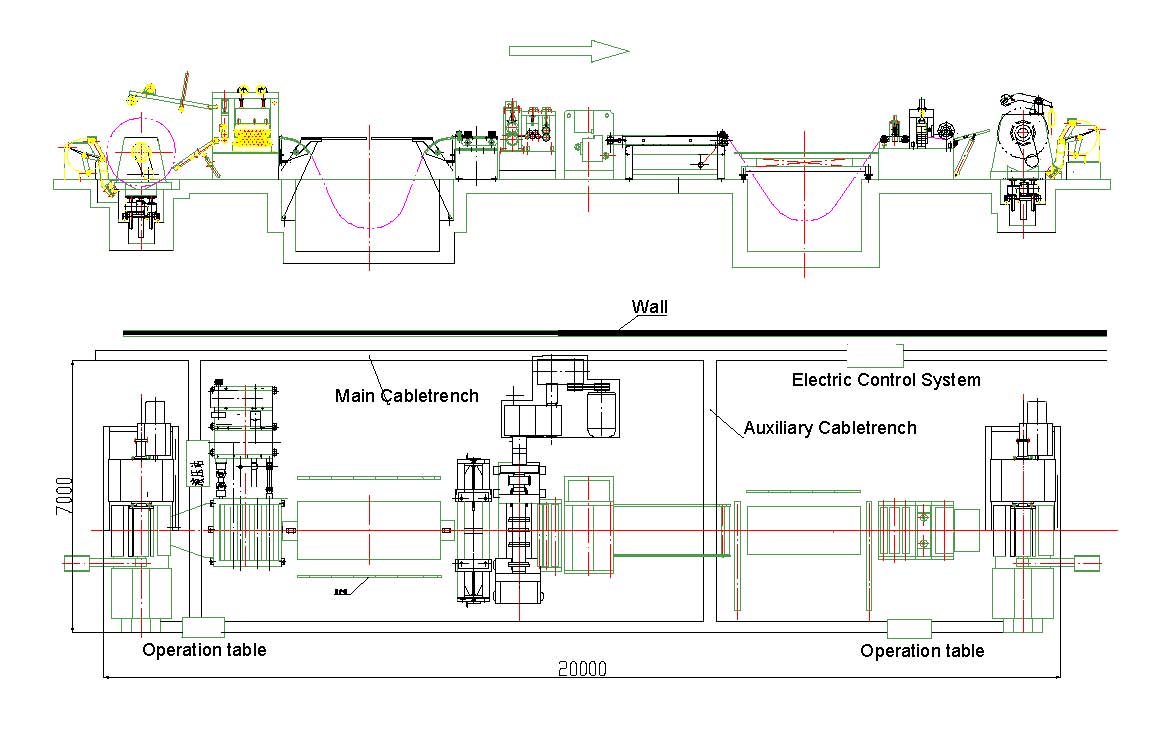

Process Flow

Coil Lifter ---Cantilever Decoiler (with Support Arm) --- Pinch Roll and Leveler (with Snubber Roller) --- Hydraulic Loop Bridge --- Side Guide Device --- Slitting --- Precision Leveling & Measuring --- Scrap Recoiler --- Shearing Machine --- Conveyor --- Hydraulic Lifting Platform (Loop Bridge) --- Pre-separating and Damping Device --- Recoiler --- Hydraulic Unload Cart