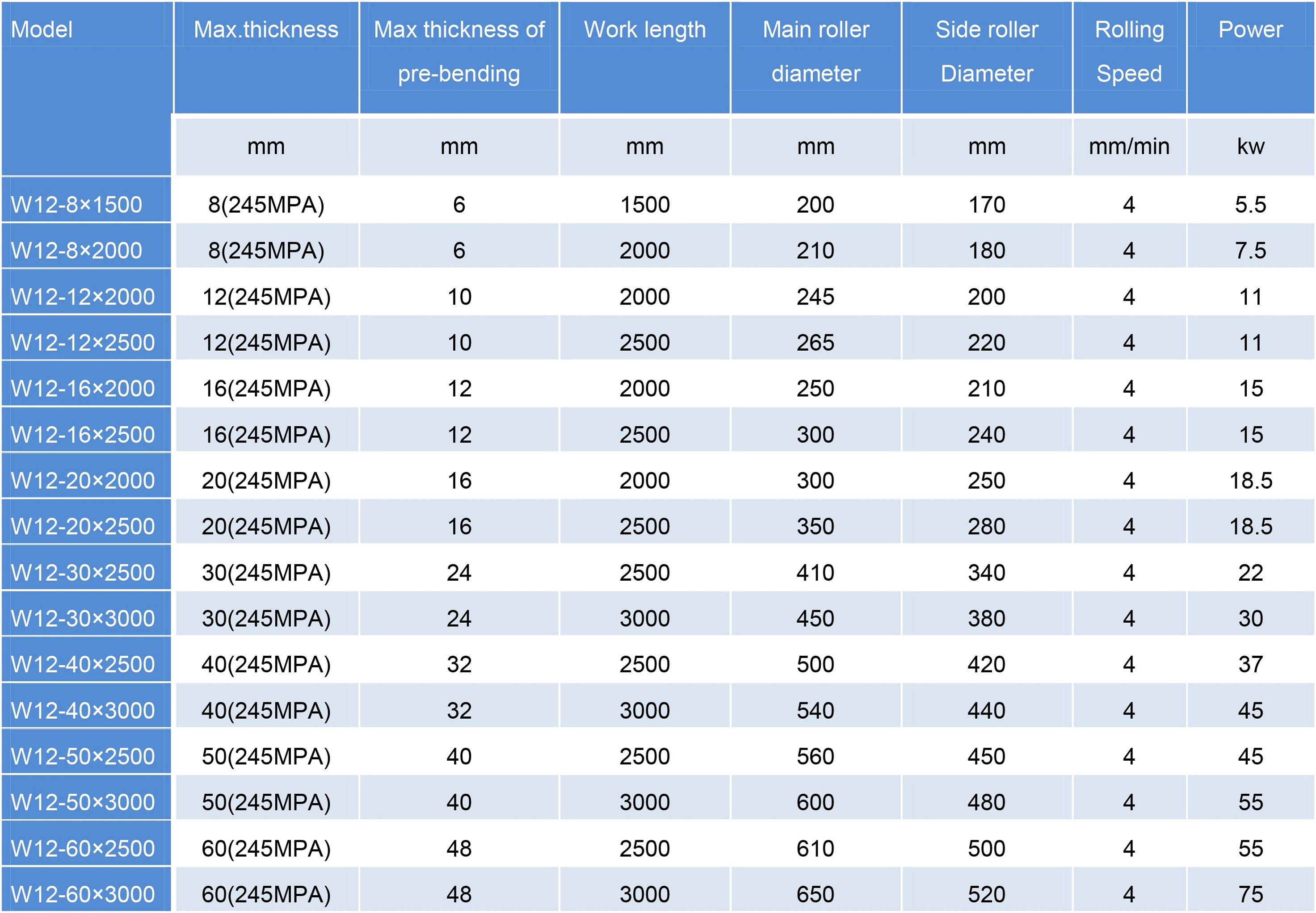

4-Roller Plate Rolling Machine

The structure of the machine is four roll type, the top roller give priority to drive, through the reducer gear and the output of the roller gear meshing, provides torque with screw sheet, the next roller lift vertically,

1. 4-roller type for bending the plate into a cylinder or arc or cone shape product

2. One time to finish the process as pre-bending and rolling.

3. Top roller as the drive roller driven by the hydraulic motor

4. Bottom roller works up and down to clamp the material by hydraulic

5. Side Roller can work separately

6. PLC NC control and overload protect